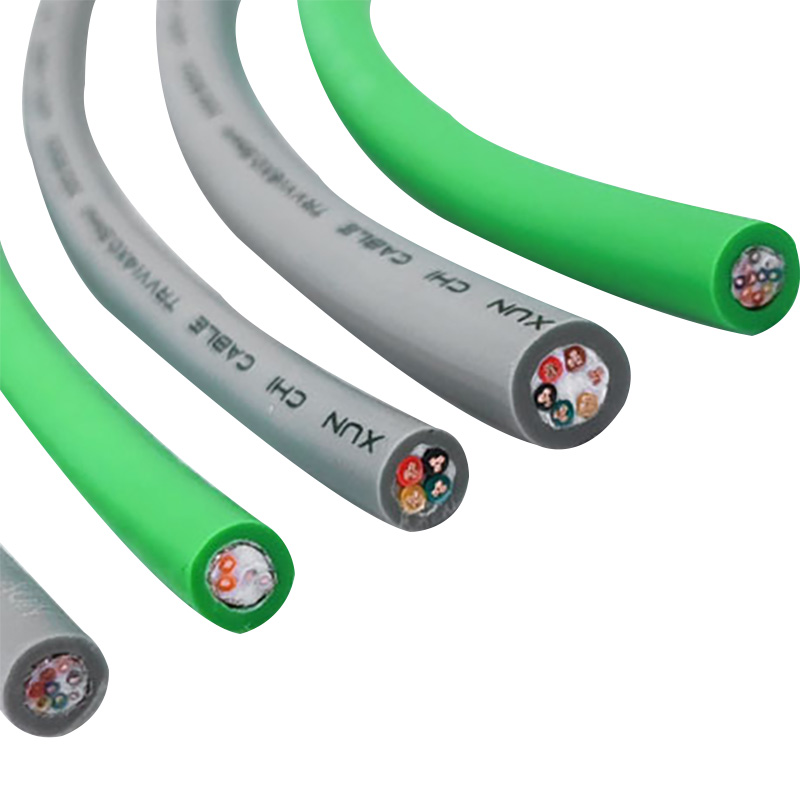

STP Cable

Shielded Twisted-Pair Robot Drag Chain Cable

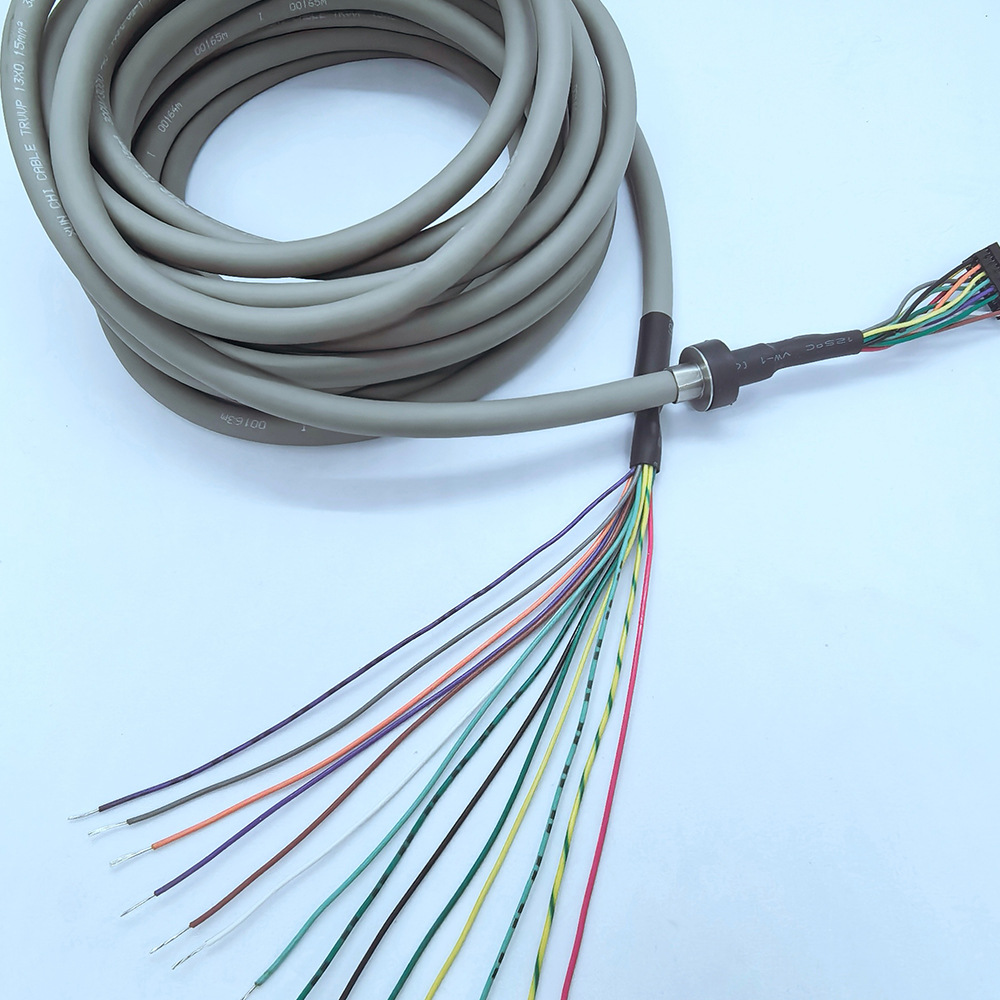

- Product Brief: Application Scope of Inverter Cable】It is suitable for installation in dry or humid indoor environments, under free continuous reciprocating motion without strong stress relief or forced guidance, and in bending scenarios in industrial use environments, such as woodworking machinery, machine tool p

Description

Shielded Twisted-Pair Robot Drag Chain Cable

Our shielded twisted-pair robot drag chain cable is a high-performance wiring solution engineered specifically for the rigorous operating conditions of industrial robots, automated production lines, and CNC machinery. Designed to withstand continuous flexing, torsion, and mechanical stress inside drag chains, this cable delivers stable data transmission and reliable signal integrity even in harsh industrial environments.

Core Features

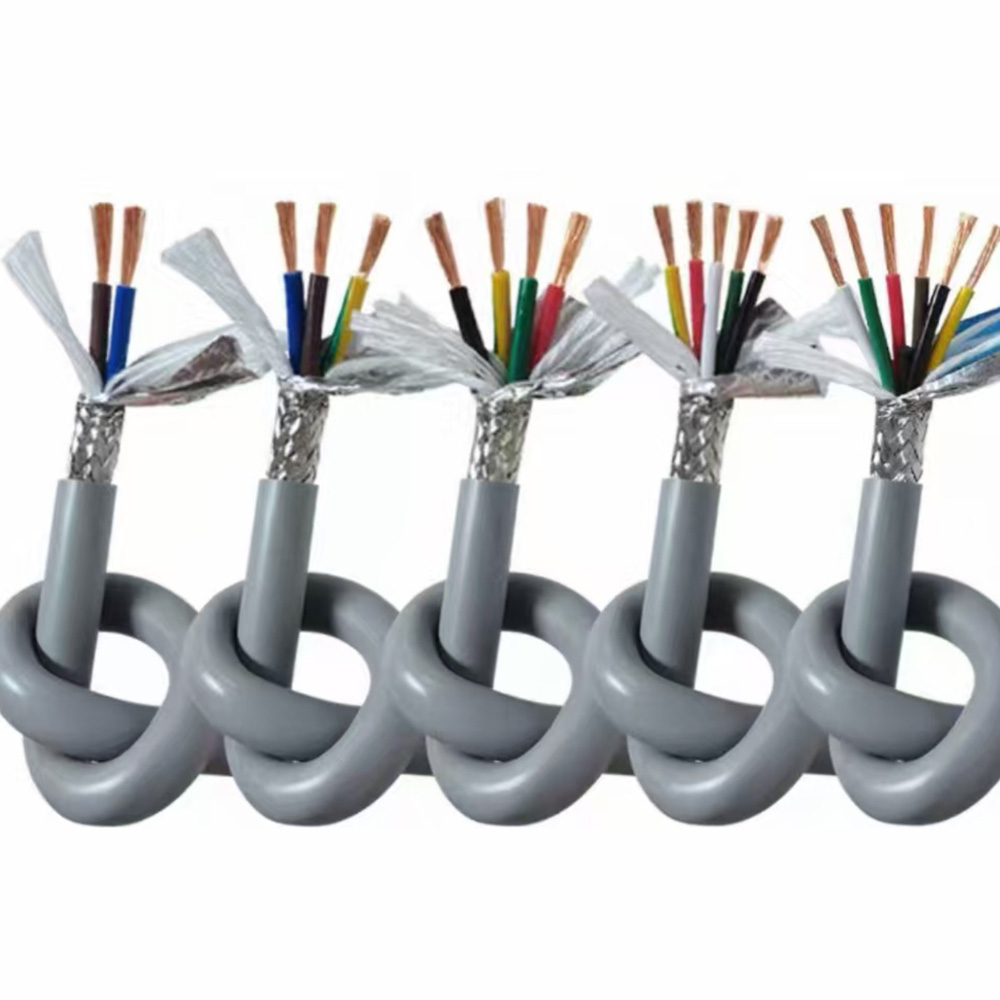

Shielded Anti-interference DesignThe cable is integrated with a full-coverage tinned copper braided shield, which effectively blocks electromagnetic interference (EMI) and radio frequency interference (RFI) from surrounding industrial equipment such as motors, inverters, and high-voltage devices. This ensures error-free data transmission for precision control systems.

Flexible Twisted-Pair StructureThe twisted-pair conductors are twisted at an optimized pitch to minimize crosstalk between pairs, guaranteeing high-speed, low-loss signal transmission. The conductors are made of oxygen-free copper, offering excellent conductivity and low resistance to reduce signal attenuation during long-distance transmission.

Superior Flexibility and DurabilityCrafted with a high-quality thermoplastic elastomer (TPE) outer sheath, the cable exhibits outstanding wear resistance, oil resistance, and corrosion resistance. It can withstand millions of flexing cycles, making it ideal for continuous reciprocating movements in robot drag chain systems.

Wide Operating Temperature RangeSuitable for operating temperatures from -40°C to +80°C, this cable adapts to extreme cold and hot industrial environments, without performance degradation in low-temperature workshops or high-heat production sites.

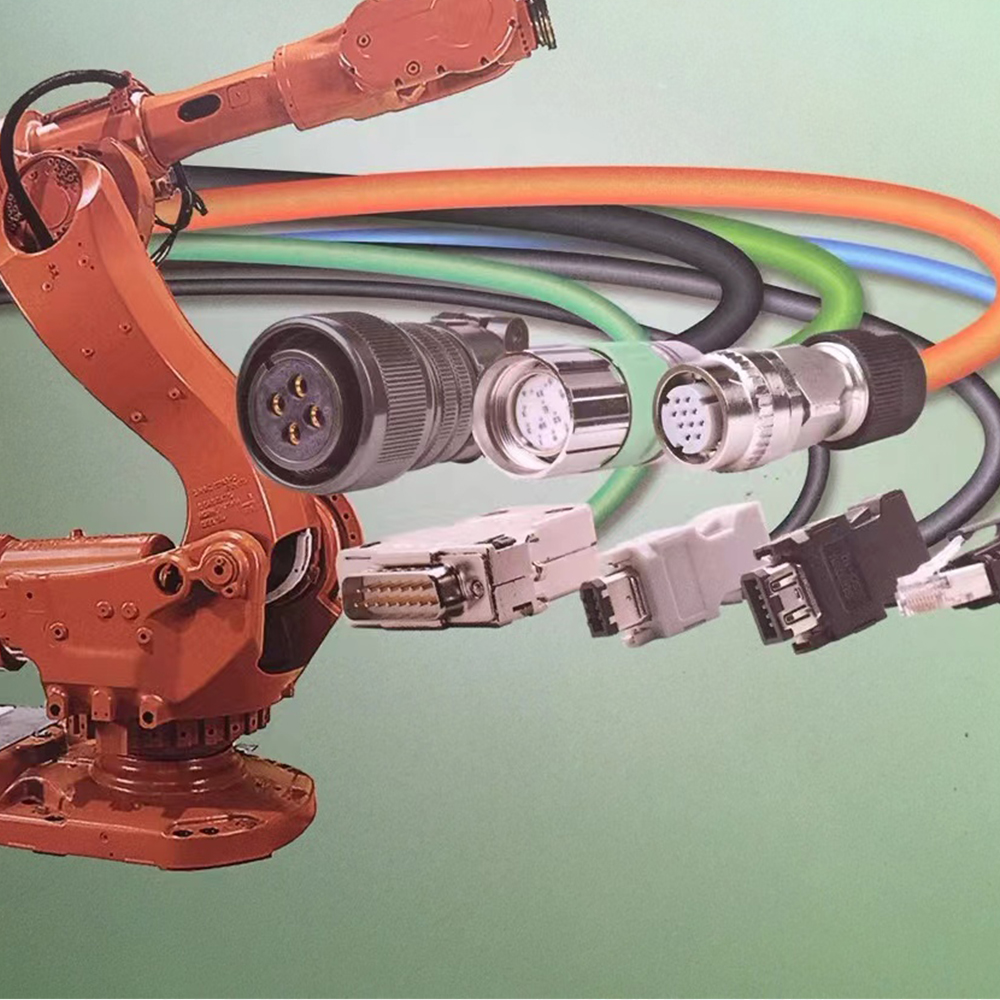

Typical Applications

Industrial robot arm control systems

Automated production line data transmission links

CNC machine tool drag chain wiring

Material handling equipment signal cables

High-precision testing instrument connections

Technical Advantages

Compared with ordinary cables, our shielded twisted-pair robot drag chain cable has higher mechanical strength and longer service life, reducing the frequency of cable replacement and maintenance costs for enterprises. Its compliance with international standards such as CE and RoHS also ensures it meets the requirements of global industrial markets.

FAQs

Common causes of flexible cable failure include:

Over-Bending: Bending the cable beyond its minimum bend radius (MBR) damages conductors and insulation. Prevention: Adhere to the manufacturer’s MBR specifications and use cable management tools (e.g., cable tracks) to control bending paths.

Abrasion & Wear: Friction with surrounding components wears down the sheath. Prevention: Choose cables with wear-resistant sheathing (e.g., PUR) and install protective conduits or cable carriers.

Environmental Damage: Exposure to chemicals, moisture, or extreme temperatures degrades materials. Prevention: Select cables rated for the specific environment and use sealing or shielding where necessary.

Incorrect Installation: Tension, kinking, or improper grounding can strain the cable. Prevention: Follow installation guidelines, avoid pulling cables tightly, and ensure proper grounding for shielded cables.

Eelecting the appropriate flexible cable requires considering several key factors:

Movement Type: Determine if the cable will undergo bending (single or multi-axis), twisting, or torsional movement—this dictates the required flexibility (e.g., high-flex for robotic arms vs. medium-flex for simple folding applications).

Environmental Conditions: Assess temperature range (from extreme cold to high heat), exposure to chemicals, oil, water, or UV radiation—choose insulation/sheathing materials (e.g., PUR for oil resistance, TPE for wide temperature tolerance) accordingly.

Electrical Requirements: Confirm voltage rating, current capacity, and signal transmission needs (e.g., shielded flexible cables for reducing electromagnetic interference in data applications).

Mechanical Durability: Evaluate the number of bending cycles required (e.g., millions of cycles for long-life industrial use) to select cables with suitable conductor stranding and sheath thickness.

lexible cables are widely used in industries and equipment where frequent movement is involved. Common applications include:

Industrial Automation: Robotic arms, automated guided vehicles (AGVs), and linear motion systems.

Material Handling: Conveyor belts, hoists, and cranes that require cables to bend with mechanical movement.

Medical Equipment: Portable devices (e.g., ultrasound machines), surgical robots, and patient monitors that need flexible wiring for mobility.

Consumer Electronics: Laptop power cords, headphones, and wearable devices where flexibility ensures user comfort and product longevity.

Automotive Industry: Wiring for folding side mirrors, seat adjustments, and retractable door handles.

A flexible cable is a type of electrical cable designed to withstand repeated bending, twisting, and movement without compromising its electrical performance or structural integrity. Unlike standard fixed-installation cables, which are engineered for static or minimal-movement applications, flexible cables feature specialized constructions—such as fine-stranded conductors (instead of solid or coarse-stranded ones), flexible insulation materials (like PVC, TPE, or PUR), and robust sheathing—that enhance their durability under dynamic stress. This design allows them to be used in scenarios requiring constant motion, such as robotic arms, conveyor systems, and portable equipment.

In industrial scenarios where dynamic motion and signal integrity coexist, standard cables often fail to meet requirements—either lacking flexibility for long-term bending or failing to block interference for precise signals. TRVVPS Twisted Pair Shielded Drag Chain Cable solves these pain points through its integrated design of twisted pairs, shielding, and high flexibility, ensuring reliable, stable, and long-lasting performance. It is a critical cabling solution for upgrading automation levels and improving production precision in modern manufacturing.